Dedicated Customer Teams & Agile Services

Overview

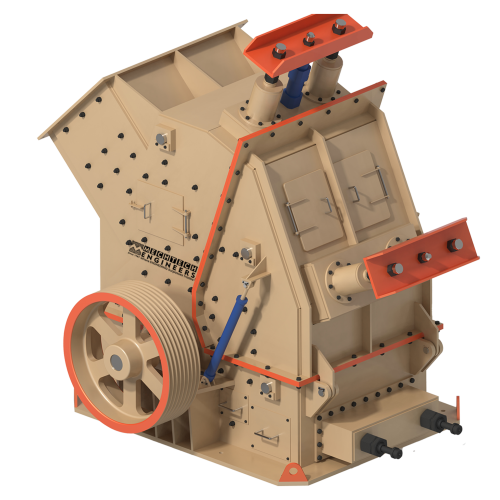

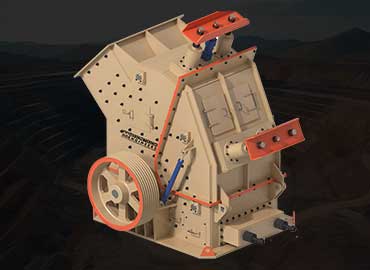

Mechtech’s HSI MH-Series is the perfect crusher for secondary crushing in the limestone, recycling concrete, and cement industries for minerals such as aggregate, gypsum, limestone, calcium carbonate, dolomite, and more.

Aggregate production is more concentrated in the primary stage than in the secondary stage, resulting in higher reduction ratios and cubical shapes.

Salient Features

OPENING AND CLOSING

BLOW BARS

APPRON ADJUSTMENTS

INSPECTION DOOR

side, and back.

ROTOR DESIGN

THREE-APRON DESIGN

| MODEL | ROTOR DIAMETER (MM/INCH) | ROTOR WIDTH (MM/INCH) | MAX FEED SIZE (MM/INCH) | MAX POWER (HP/KW) | THROUGHT PUT CAPACITY (TPH) |

|---|---|---|---|---|---|

| MH 8060 | 800/31 | 600/24 | 200/8 | 50/37 | 60 |

| MH 8080 | 800/31 | 800/31 | 200/8 | 75/56 | 90 |

| MH 1060 | MH 1060 | 600/24 | 250/10 | 60/45 | 90 |

| MH 1080 | 1000/39 | 800/31 | 300/12 | 100/75 | 120 |

| MH 1010 | 1000/39 | 1000/39 | 300/12 | 120/90 | 165 |

| MH 1210 | 1200/47 | 1000/39 | 400/16 | 150/112 | 180 | MH 1212 | 1200/47 | 1200/47 | 400/16 | 180/134 | 250 | MH 1412 | 1400/55 | 1200/47 | 500/20 | 500/20 | 280 | SDRC 1414 | 1400/55 | 1400/55 | 600/24 | 270/200 | 350 | MH 1416 | 1400/55 | 1600/63 | 600/24 | 300/223 | 450 | MH 1616 | 1600/63 | 1600/63 | 800/32 | 335/250 | 500 | MH 1618 | 1600/63 | 1800/70 | 800/32 | 425/300 | 600 |

FAQ

Yes, we offer installation and maintenance services to ensure that our equipment operates at peak performance throughout its lifespan.

Yes, we offer customized solutions to meet the specific needs of our customers. Our team works closely with customers to understand their unique requirements and develop tailored solutions.

Yes, we offer training for equipment operators to ensure that they are properly trained on the use and maintenance of our equipment.

Our crushing equipment is manufactured in our state-of-the-art facility, located in Vadodara, Gujarat. We use the latest technology and equipment to ensure the highest level of quality and precision.

Case Studies

HSI

HSI Crusher – Perfect crusher for secondary crushing

Mech Tech ‘s HSI is the perfect crusher for secondary crushing in the limestone, recycling concrete, and cement industries for minerals such as aggregate…